Turning fruit and plastic wastes into a material used in the water purifier

Plastic pollution is a big problem. Improper plastic waste management can have a negative impact on the environment, wildlife, and public health.

Likewise, food waste is an economical, humanitarian and environmental crisis. One-third of the food produced today is wasted. Meanwhile, global food production is gradually increasing, causing concerns about the disposal of food waste, the best example being fruit and vegetable wastes (FVW). A feasible option is to establish an FVW refining platform to introduce the waste stream into the production of biodegradable bio-based plastics.

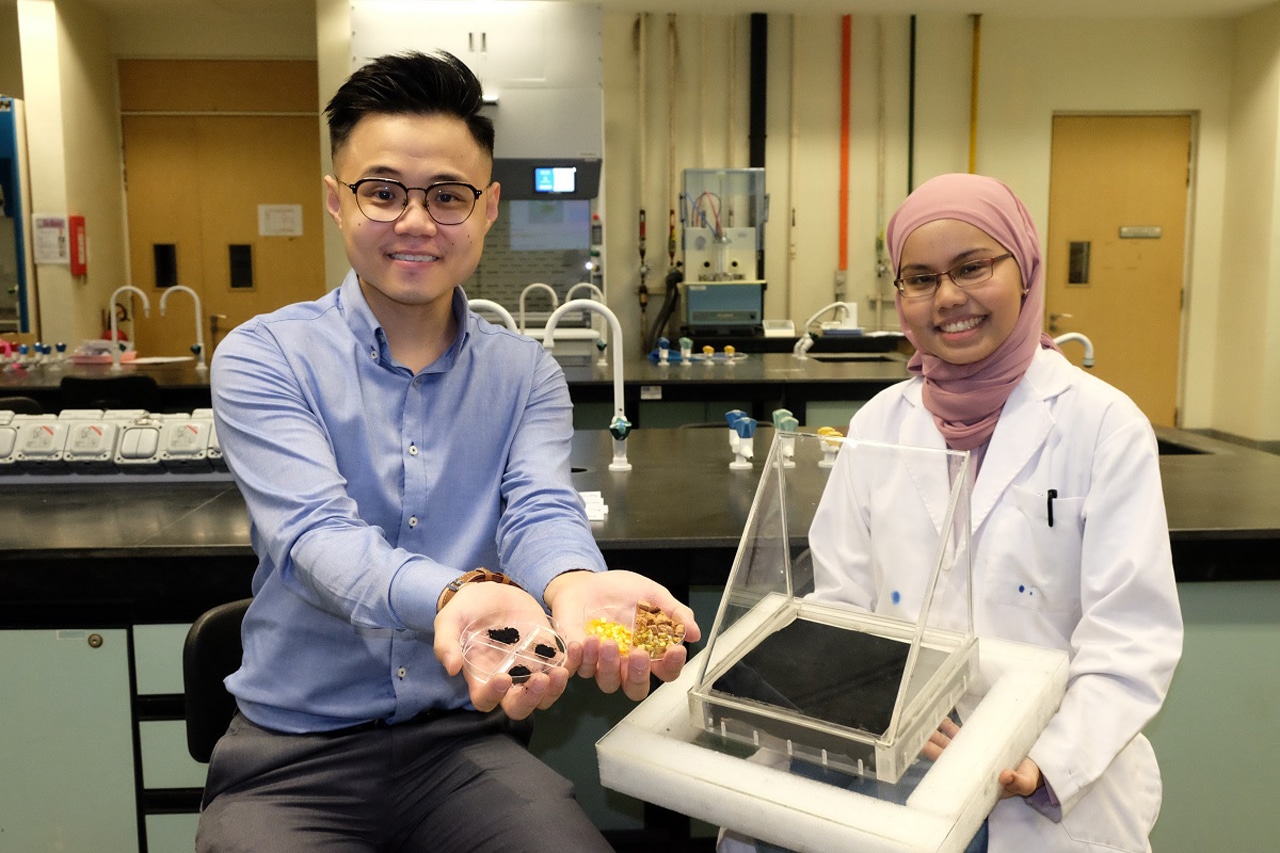

This new study has developed a new strategy to address these concerns. A scientist from Nanyang Technological University in Singapore has turned fruit and plastic waste to create ultra-thin material for solar-powered water purification.

The material made from recycled fruit waste has exceptional light-to-heat conversion efficiency and can be used in equipment to purify dirty water. The scientist mainly used fruit waste like coconut husks and orange and banana peels to make Mxenes.

Mxenes are electrical-conducting compound that has similar properties to graphene. However, unlike graphene, MXenes are made from other elements besides carbon, giving them better light-to-heat conversion properties. They are stronger than steel and lightweight: the properties that enable them to replace conventional materials in industrial applications such as energy storage, optical, and sensors.

This is where Asst Prof Ang comes in with his simple method of carbonizing fruit peels to make MXenes.

The prototype has an average light-to-heat conversion efficiency of 90%, which is ~30% higher than that of the commercial solar absorber. As a result, the water production rate is ~50% higher than that of the commercial ones.

The MXenes material can be reused as it is not directly in contact with seawater, rather, only a thin layer of MXenes material is needed to deposit on top of the water absorber (i.e., air-laid paper).

He stated, “The air-laid paper is like “tissue paper,” which is cheap. Typically, during the day, when there is sunlight, the seawater’s salt will crystallize onto the air-laid paper. However, at night, those crystallized salt will dissolve back into the sea, making the still solar device environmentally sustainable.”

“The synthesis process is three times cheaper than commercial methods because the source that we use (fruit waste) is free of charge.”

Prof Ang is planning to use the material in solar stills- which use sunlight to distill dirty water, energy storage, and battery manufacturing.

Conventional distillation is only feasible in industrialized nations due to the high infrastructure and energy expenses involved. Compared to current distillation techniques, Asst. Prof. Ang’s solar still is more affordable, portable, and environmentally benign.

Journal Reference:

- Marliyana Aizudin, Ronn Goei et al. Sustainable development of graphitic carbon nanosheets from plastic wastes with efficient photothermal energy conversion for enhanced solar evaporation. Journal of Materials Chemistry A. DOI: 10.1039/D2TA02092K

JOURNALJournal of Materials Chemistry AUNIVERSITYNanyang Technological University

![iFi's GO Bar Kensei Dongle DAC Supports K2HD Technology With Some Samurai Swagger [Updated] iFi's GO Bar Kensei Dongle DAC Supports K2HD Technology With Some Samurai Swagger [Updated]](https://i0.wp.com/cdn.ecoustics.com/db0/wblob/17BA35E873D594/33FF/45A11/QTXOLJR4xDKSNMMk2WlTgjaIlvSgcYpeU1xJzUwIoYs/ifi-go-bar-kensei.jpg?w=768&ssl=1)